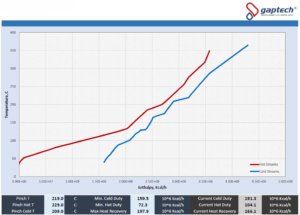

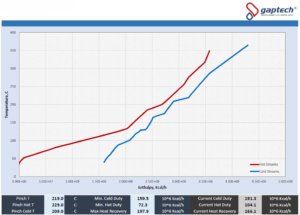

Pinch analysis is a methodology for minimizing energy consumption of chemical processes by calculating thermodynamically feasible energy targets (or minimum energy consumption) and achieving them by optimizing heat recovery systems, energy supply methods and process operating conditions. It is also referred to as process integration, heat integration, energy integration or pinch technology.

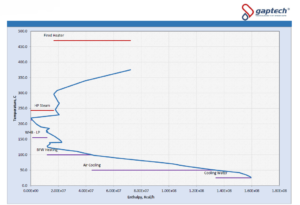

Pinch analysis is a tool for process integration. Through pinch analysis the minimum hot and cold utilities demands can be thermodynamically predicted with given operating temperatures and Minimum Approach Temperature (MAT). These minimum utility demands (called targets) can be met by following pinch rules for Heat Exchanger Network (HEN) design.

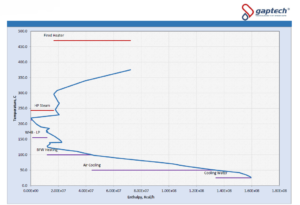

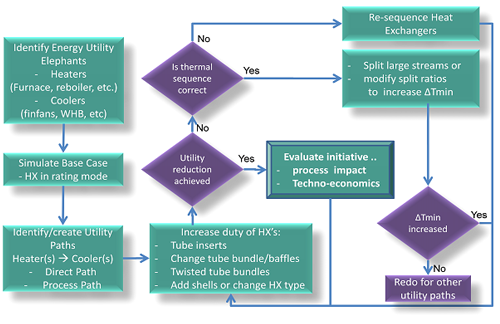

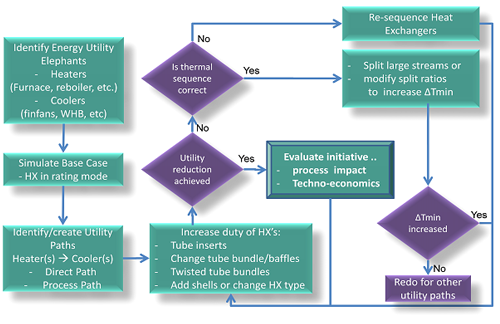

Beyond Pinch is a methodology developed by GAPTECH for Heat Exchanger Network (HEN) retrofit. It also proven to be an efficient tool for HEN design and review during project phase as it provides maximum benefits with the minimum modification to the original design. This methodology targets the easy heat recovery retrofits requiring minimum modifications to the network and therefore minimum disruption to plant configuration and lower cost.

The methodology helps in identifying the heat recovery alternatives at an order of increasing complexity and cost; hence giving the plant owners the ability to select the depth of modifications to the plant’s configuration they want to adapt.

Download White-Paper

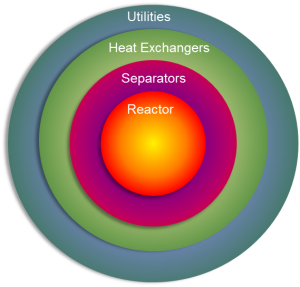

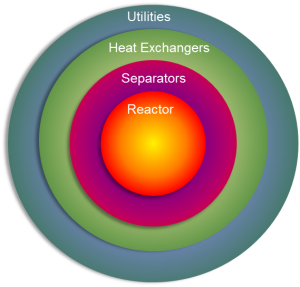

Process unit design follows the sequence of what is called the Onion Model starting with the reaction, separation, heat exchange, hydraulics respectively. While this sequence ensure the integrity of the system it may not achieve the best energy efficiency point for the process unit or overall the process plant.